How to Make Cuts With a Jigsaw

The jigsaw is undoubtedly one of the most useful tools for DIYers. However, for beginners, it can be tough to know where to start when you first get it out of the box. By the end of this guide, you’ll understand exactly how it works, the equipment you’ll need, and how to start cutting safely.

What Kind of Project is a Jigsaw Suitable For?

A jigsaw is an incredibly versatile tool that can be used in a variety of situations. If you’ve got a project planned, then it’s pretty likely that it will come in handy.

Jigsaws are most effectively used for straight cuts, cutting curves and shapes into wood panels or other sheets of material. As a result, the tool can be applied to a huge range of projects in the home, garden, or workplace.

When it comes to power tools, a jigsaw is always a wise investment. If you enjoy DIY, you’ll be shocked just how often you’ll pick it up and how much value you get out of it in the long run.

How Does a Jigsaw Work?

With any power tool, it’s important to understand exactly how it works if you want to use it to its maximum potential. This is definitely the case with a jigsaw – once you know what makes it tick, you’ll be able to take on any DIY project that comes your way.

A jigsaw is effectively made up of two main parts – a motor and a saw blade. When the motor is powered, it rapidly raises and lowers the jigsaw blade. When the jigsaw is placed flush against a piece of wood, the blade is dragged through the work, creating the cut.

You can think of this tool as operating in a similar way to a sewing machine – where the needle moves up and down continuously, at a right angle to the machine. Of course, this is a somewhat simplified explanation, but it gives you a basic idea of how a jigsaw works.

Control Options

Jigsaws usually provide users with plenty of features to help them control their tool. If you want to be as accurate as possible with your cuts, then speed control is going to be one of the main features to look out for.

By adjusting the blade speed setting, you can alter how quickly the saw cuts through a material. You can slow down for more intricate sections and speed up for straight edges and cross cuts. The best jigsaws will let you change the tempo as you cut, giving you maximum control over the blade.

Another feature that is built into premium jigsaws is orbital control. This is when the user can set their blade to move forwards and backwards, as well as up and down. An orbital action provides a much more aggressive cut, so can help you slice easily through the most abrasive materials.

Choosing the Jigsaw Blade

A jigsaw can shape a range of materials including sheet metal, ceramic tiles, and plastic. There are different jigsaw blades designed to cut different materials, so choosing the right blade is an extremely important step in using a jigsaw effectively.

You also need to know which type of blades your jigsaw accepts:

U-Shank VS T-shank Blades

These are the two main types of jigsaw blades. The only difference between U-shanks and T-shanks is the way that they connect to the jigsaw – U-shanks are attached via a small screw, whereas T-shanks are held in place by a blade clamp.

These days, most manufacturers use T-shanks since it’s typically easier to switch between different blades with the clamp setup. However, there are still some models around with a U-shape connection so it’s essential to know which one your jigsaw has.

Blade Types

High Carbon Steel

HCS blades are probably the most common jigsaw attachments, thanks to their versatility and the range of materials that they’re compatible with. An HCS blade is perfect for cutting softer materials, including softwood, fibre boards, and flexible plastics.

HCS blades are pretty flexible, which allows the user to create curved cuts with ease. They’re also pretty cheap, so you don’t have to worry too much about them getting damaged whilst you’re cutting.

High-Speed Steel

If you’re working with harder materials, then it’s likely that your HCS blades aren’t going to cut it. This is where high-speed steel (HSS) blades come into play – if you’re cutting sheet metal or perspex, then HSS is definitely the way to go.

Since HSS blades are stiffer than HCS blades, they’re typically not as flexible, making them the better chose for cutting a straight line with a jigsaw. As a result, it’s harder to cut curved edges with an HSS attachment, and they are more prone to breaking during use.

On the other hand, the hard nature of HSS blades means they are very durable and can last for a long time. It’s always worth having a couple of HSS blades in your tool kit for when you want to slice into some tougher materials.

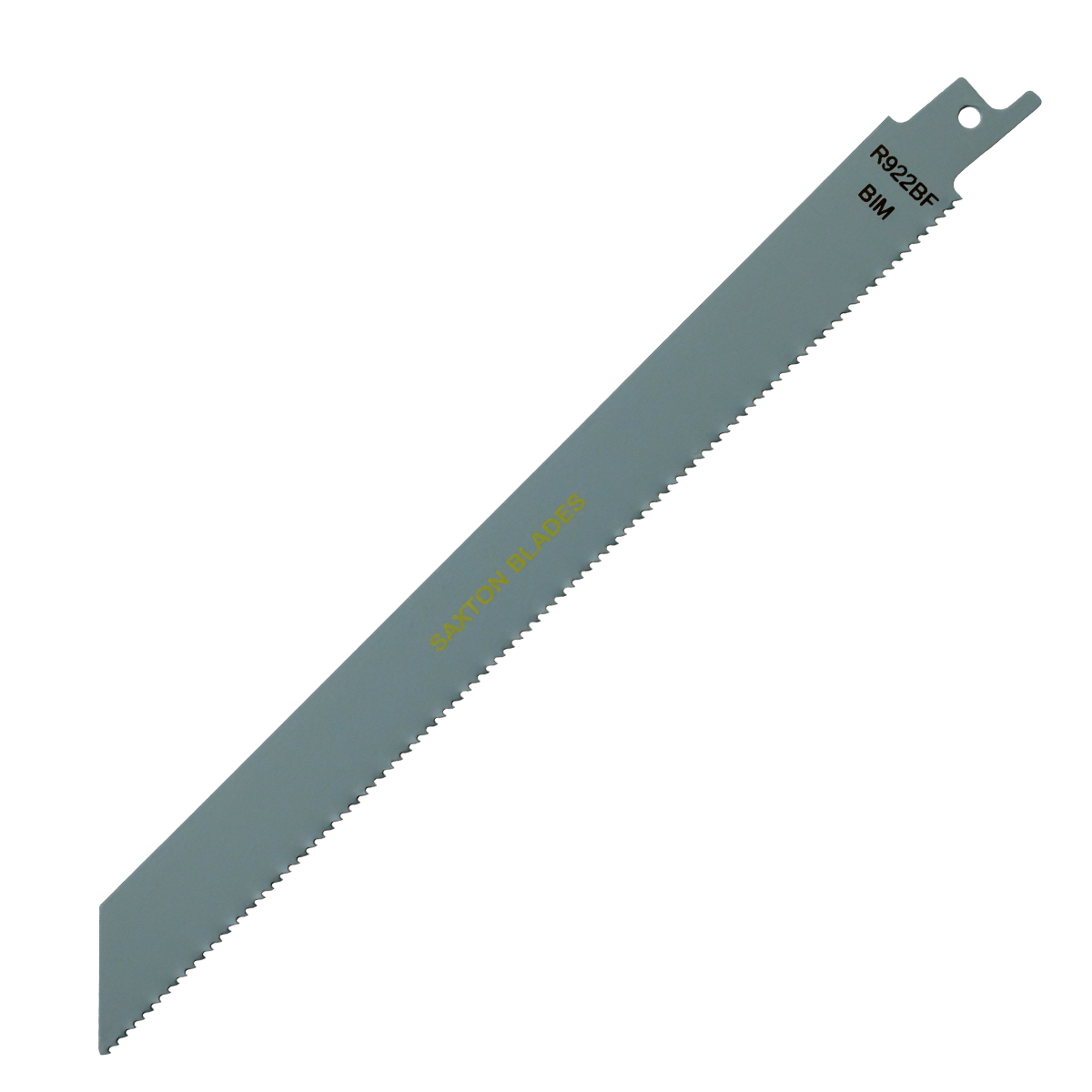

Bi-Metal

A bi-metal (BIM) blade combines the flexibility of HCS with the strength and cutting power of HSS. It achieves this by taking the teeth from an HSS blade and placing them along the body of an HCS blade. This innovative approach has proven attractive to many jigsaw users and is a great solution for anyone who finds themselves working on different materials a lot.

The only drawback of a BIM blade is the price. They are significantly more expensive than their HCS and HSS counterparts, thanks to the complicated process that goes into crafting them. Having said that, their level of durability means you’ll be able to use them for a long time before they need replacing.

Tungsten Carbide

The final type of blade to be aware of is tungsten-carbide (TC). A TC blade is extremely hard and is used for cutting through very abrasive materials, such as ceramic tiles and reinforced plastic.

Most people won’t require a TC blade, but if you’re working on a kitchen or bathroom, then it might be worth looking into.

What Else Will I Need?

There are a couple of other tools that you’ll require if you want to use your jigsaw safely and effectively.

Clamp

One of these is a clamp. A clamp is used to hold the material against a workbench whilst you cut it with the jigsaw. You really don’t want your piece of wood or metal to be sliding around whilst you cut it – this will make it almost impossible to follow a cutting line and more importantly, it will be pretty unsafe.

Safety Equipment

When you’re wielding power tools that can cut straight through sheet metal, safety should always be your number one concern. Before attempting any cutting, make sure you’ve got yourself pairs of gloves, goggles, earplugs, and sensible footwear.

How to Cut With a Jigsaw

Now that we’ve discussed how a jigsaw works and all the equipment that we’ll need, we can finally get to the fun part. Although making your first cut might seem daunting, once you get started you’ll quickly get the hang of how everything works.

If you’ve picked out that correct blade and length for the material you’ll be cutting, then you’re ready to start.

Step 1: Sketch a Cutting Line on Your Work

We can’t stress enough how important and helpful it is to mark out a cutting line on your work before you begin. Sketch out a pencil mark to help guide your cut, this way, you’ll always know where you’re up to with your cut and it’s much easier to stay in control of what you’re doing.

Step 2: Secure the Work to the Clamp

We’ve already mentioned why it’s important to use a clamp in the previous section. Making sure your work is securely fastened in place will make the cutting experience run much more smoothly, and you’re much less likely to have any problems.

Step 3: Set Up Your Saw and Correctly Position It

Ensure that the correct blade is fully in place inside the saw. Check that it doesn’t move when you apply pressure and satisfy yourself that it isn’t going to come loose when you start cutting.

Place the saw into position. If you’re cutting a shape out of your work, then you’ll need a starter hole (or plunge cut) that you can insert the blade into. Starter holes are formed by drilling through the wood whereas plunge cuts are holding the jigsaw at an angle and using the edge of the blade.

Once the saw is lined up with the edge of your work or inserted into a starter hole, you’re ready to start cutting. Make sure the blade teeth are pointing away from you since you’ll be pushing the saw rather than pulling it.

Step 4: Make the Cut

Gently pull on the trigger and slowly push the saw along your cutting line. It’s very tempting to want to push harder against the work to speed up the cut, but this makes the saw much harder to control. Instead, let the saw do the work and gently guide it along your desired curves.

You can use the variable speed adjuster if you come up against more resistance and the blade is struggling to cut through or if you need to switch between straight cuts and curved cuts. Once you’ve finished your cut, let the excess wood drop to the floor and the blade come to a stop before you lift the saw away from the work, this will leave you with a nice, clean cut.

Tips for Cutting Different Materials

The material that your cutting into is going to have a big impact on how your saw performs. Whether you’re cutting a piece of metal, plywood, plastic, or ceramic, it’s always good to know a few tips and tricks to give you the best result.

Wood

Wood is probably the easiest thing to work with for jigsaws. However, wood comes in loads of different variations – you’ve got softwood, hardwood, plywood, MDF, and much more. Each of these types of wood is going to feel different underneath your saw.

That being said, the main thing to remember with woodworking is to let the saw do the work. As soon as you push forward too much, your blade is going to be thrown straight off your guideline. Resist the urge to do so and only ever apply gentle forward pressure.

If you’re looking to get a clean cut through wood, check out our full range of jigsaw blades for cutting wood.

Metal

If you want to cut metal, then the biggest tip we can give you is to use the right jigsaw blade. A BIM blade is going to be your most efficient bet, but HSS blades are good too. By choosing a decent blade, you’ll be able to cut metal without damaging your work or your saw.

When you’re cutting metal with metal, you can get some serious rattle going through the work. To stop this from happening and to keep your line steady, be sure to apply plenty of downward pressure to hold everything in place.

We offer specific jigsaw blades for cutting through metal, take a look at our range of metal saw blades.

Ceramic

For jigsaws, ceramic might well be the most difficult medium to work with. Ceramic is very brittle, and can easily crack when using power tools. To prevent this, make sure you’re carefully controlling the blade speed and letting the cutting edge slowly make its way through the ceramic.

You also need to be using a specialist cutting blade. Standard HSS or HCS teeth aren’t going to be enough. Instead, you want to equip a Tungsten Ceramic or diamond-tipped blade for the best jigsaw cut.

Plastic

It’s true that jigsaws can be used to make cuts in plastic, but plastic is a very broad term that encompasses a lot of different materials. Some plastics are very soft and pliable, whilst others are almost as hard as metal.

You can’t just attach a blade and expect it to work with every kind of plastic. If you are going to be using your power tool with plastic, it’s important to know the properties of the particular piece that you’re working with.

If it’s a softer plastic, then you can cut it with an HCS or HSS blade. If it’s much harder, then a bi-metal or carbide blade might be more appropriate to prevent the plastic from splintering. These are the considerations you always have to make when using cutting power tools.

Whether you are a beginner or looking to improve your skills when it comes to using a jigsaw power tool, our guide gives you all the information for a successful, clean cut through a variety of different materials. Make sure to choose the correct safety equipment, fully understnd the material you are working with and make sure to use the correct, and high quality saw blade for the job.

At Saxton Blades, we offer a wide range of high-quality jigsaw blades at low prices. With over 11,000 4* reviews, we are proud our products are built for the task.

Browse our full range of jigsaw blades to complete your DIY projects.